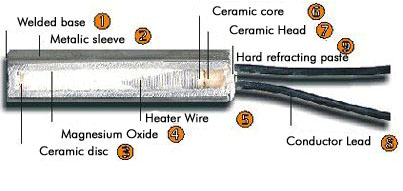

Durawatt cartridge heaters are made of means of compression for all their components, with the aim of lengthlening their working life

The conductor wire is wound round the hard ceramic body into which the conductor lead is inserted, with no connexion (sometimes, a connexion may occur on the outside of the cartridge). Ceramic discs and heads are inserted to obtain insulation and protection. Everything is coated with checked pure granulometric magnesium oxide to ensure total completion.

Later a process of compression and another of rectificatifying the surface is carried out until the required measurement is calibrated. Finally, a strict quality control is carried out to guarantee the best working of the cartridge.

|

|